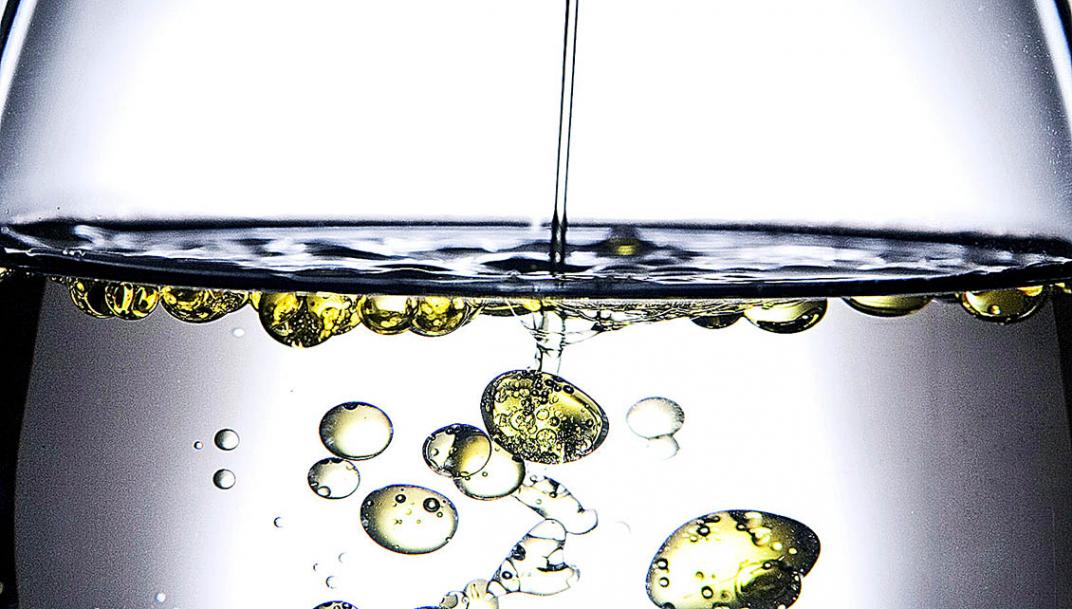

Liquid level sensors are used for detecting the levels of the liquid or the interfaces between the liquids such as oil and water or the liquids and solids. This tool can be described as a sensor or transducer, or the integrated system with the instrumentation and the control capabilities. The point liquid level sensor often triggers an alarm or turn off the system based upon the specific limit.

As it is not safe and possible to view the interior of huge tanks and vessels operating in industry, thereby for this purpose, liquid level indicators are used to measure point level measurement or continuous level measurement of liquid content to maintain quality and standard.

There is a variety of point level detectors and continuous monitoring level indicators available for measurement of liquids and solids. Each technology currently in use in the market has its own features, specifications and pros and cons. These liquid level sensors have application in a number of industries.

They are being used in controlling the level of fluids in water treatment plants, chemical refinery units, water and waste material factories and oil manufacturing plants. They have various applications in power generating plants, pulp and paper making factories and beverage and food producing plants. A number of these gauges are being used in medical labs and gauges too. Apart from that, they are used for measuring of fluid in safety equipment in marine, aviation and vehicles too. Below are some of the technologies used in the various industries:

Ultrasonic Level Indicator:

Ultrasonic sensors are non contact gauges that are mostly used when the measurement is of bulk solids and highly viscous liquids. Most of the time, they are used in the pump control, open channel flow and water treatment industry. They also have application in marine, vehicle and aviation. Many safety equipment, such as fire extinguishers used ultrasonic technology for measurement of liquid gases level inside the tank. These indicators release very high frequency acoustic waves (ranging from 20 kHz to 200 kHz) which reflect back and detect by emitting transducer. Since ultrasonic sensors use “electric” signals, they are considered as very intelligent and reliable devices.

Resistive Chain Level Indicator:

Resistive chain sensors are used for continuous level measurement of liquids. Inside this device is a permanent magnet attached inside the float. The signals are sent through voltage or currents, proportional to the level of the liquid being measured. These sensors are being used in liquid level detection in chemical processing, marines, waste treatment, food processing and pharmaceuticals.

Hydrostatic Pressure Level Indicator:

Hydrostatic pressure sensors are highly mounted pressure indicators and are usually used in continuous liquid level measurement. They are used in detection of the level of mostly corrosive liquids stored in reservoirs and tanks of big depth. For effective results, it is necessary to use chemically compatible materials. For open air use, there is a specially designed hydrostatic pressure indicator available in the markets.

Optical Interface Level Indicator:

Optical sensors are used for both, point level detection & continuous monitoring of solids and liquids. These include liquid-liquid interface, sediments and liquids which have suspended solids. If mounted properly, these units can be used in measurement of a variety of corrosive, organic and aqueous liquids.

Although all of the above-mentioned sensors are considered as accurate and very helpful in a number of different industries, currently ultrasonic technology is being considered as the best. One reason for this is that these ultrasonic devices are small and handy, with the advantage of being very mobile with no moving parts. Usually, these devices come with an LCD screen and headphones, enabling both audio and visual results. They are also quick, because they used ultrasonic sound waves to detect the level. Used for highly viscous liquids, they can be used in tough conditions. Latest ultrasonic sensors come with the option of ten-hour battery backup; hence no immediate power source is required. They are very useful in measurement of liquids and solids present within containers, tall or small, and come in handy in measuring liquid at its natural form too. They are moderate in price, hence preferred by the majority of industries.

VEGA develops and manufactures sensors for the measurement of level, point level and pressure as well as equipment and software for integration into process control systems. VEGA’s measurement technology sets new standards in reliability, accuracy and economy for all media and process conditions.